Proceso de diseño personalizado

Nuestro proceso de diseño personalizado de 6 pasos

Descubrimiento → Prototipo → Cumplimiento → Piloto → Producción en masa → Soporte

| Paso 1: Análisis profundo del descubrimiento y los requisitos | |

| Actividades: • Consultas técnicas detalladas (voltaje, especificaciones ambientales, necesidades de cumplimiento) • Análisis de viabilidad de materiales y componentes • Alineación de presupuesto y cronograma Entregables: • Documento formal del alcance del proyecto (aprobado por ambos equipos) Por qué es importante: • Evita cambios costosos a mitad del proyecto al fijar las especificaciones de manera temprana. |

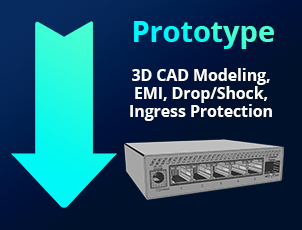

| Paso 2: Prototipado y prueba de concepto | |

| Actividades: • Modelado CAD 3D y simulaciones térmicas • Ensamblaje de prototipo funcional • Pruebas de laboratorio (EMI, caídas/golpes, protección contra la entrada) Entregables: • Prototipo funcional + informes de pruebas • Retroalimentación de Diseño para Fabricación (DFM) Por qué es importante: • Identifica fallas antes de invertir en herramientas. |

| Paso 3: Cumplimiento y certificación | |

| Actividades: • Pruebas de precertificación (FCC/CE/UL/etc.) • Pruebas de estrés ambiental (temperatura, humedad, vibración) Entregables: • Hoja de ruta de certificación (con plazos estimados) Por qué es importante: • Evita retrasos debido a fallos de cumplimiento de último momento. |

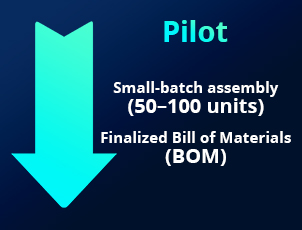

| Paso 4: Producción piloto y validación | |

| Actividades: • Ensamblaje de lotes pequeños (50–100 unidades) • Pruebas de campo en el mundo real (sitios asociados o entornos controlados) • Refinamiento basado en comentarios (cambios de componentes, ajustes de firmware) Entregables: • Unidades piloto para validación de clientes + informes de rendimiento • Lista de materiales (BOM) finalizada Por qué es importante: • Detecta problemas de escalabilidad (por ejemplo, problemas de tasa de rendimiento) antes del aumento total. • Valida la cadena de suministro: no hay escasez de componentes de último momento. |

| Paso 5: Producción en masa y escalabilidad | |

| Actividades: • Finalización de herramientas (moldes, plantillas, accesorios de prueba automatizados) • Configuración de fabricación eficiente (puntos de control de calidad en cada etapa) • Coordinación logística (centros de inventario, opciones de entrega Just-In-Time) Entregables: • Primera ejecución de producción con documentación completa (guías de montaje, registros de control de calidad) • Hoja de ruta de escalabilidad (por ejemplo, capacidad para aumentar de 1000 a 50 000 unidades al mes) Por qué es importante: • Demuestra que podemos escalar sin caídas de calidad, algo fundamental para los compradores empresariales. • Ofrece flexibilidad (por ejemplo, soporte para producción regionalizada). |

| Paso 6: Soporte de por vida y mejora continua | |

| Actividades: • Gestión de la obsolescencia (supervisión del ciclo de vida de los componentes, alertas de rediseño) • Análisis de fallos y soluciones de causa raíz (integración del proceso RMA) • Actualizaciones de firmware/software (parches de seguridad, actualizaciones de funciones) Entregables: • Garantía de soporte del producto de más de 5 años (extensible) • Notificaciones de fin de vida útil (EOL) con más de 12 meses de anticipación Por qué es importante: • Reduce el TCO (costo total de propiedad) a largo plazo, sin costos de reemplazo inesperados. • Fortalece las asociaciones: los clientes regresan en busca de diseños Gen 2. |

A diferencia de los OEM transaccionales, tratamos su proyecto como una colaboración a largo plazo, no como un pedido único.

¿Está listo para comenzar su proyecto OEM personalizado?

Obtenga su auditoría de diseño gratuita: [ ventas@benchu-group.com ]

¿Quieres un presupuesto rápido para tu proyecto OEM?

Chatea con un ingeniero ahora: [ Skype: harry1598 ]