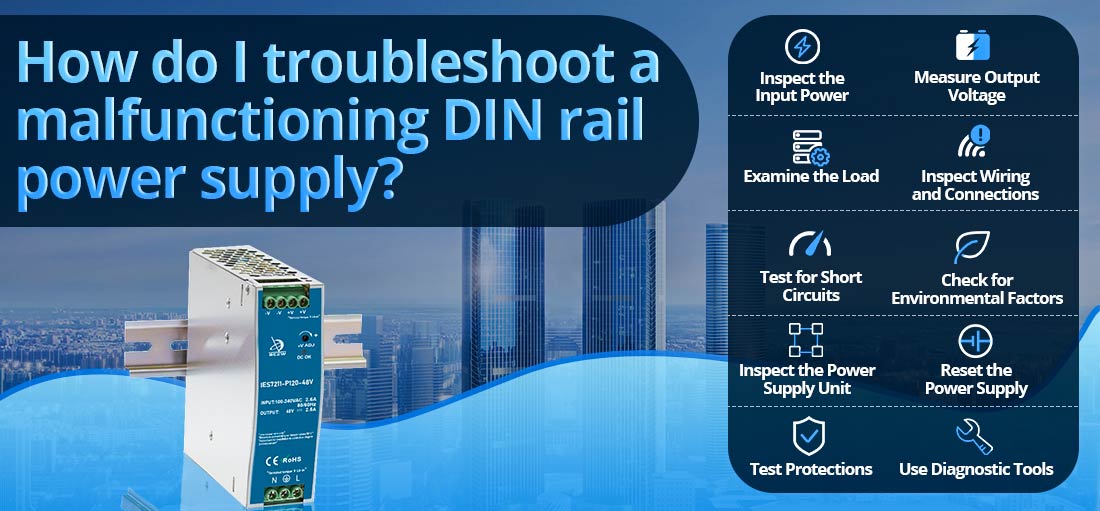

La resolución de problemas de una fuente de alimentación de riel DIN que funciona mal implica identificar y resolver sistemáticamente los problemas que afectan su rendimiento. A continuación se muestra una guía detallada para ayudar a diagnosticar y abordar los problemas de manera efectiva.

1. Síntomas comunes de mal funcionamiento

--- Sin voltaje de salida: La fuente de alimentación no proporciona ningún voltaje a la carga.

--- Voltaje incorrecto: El voltaje de salida es demasiado alto, demasiado bajo o inestable.

--- Operación intermitente: La fuente de alimentación funciona esporádicamente o se apaga inesperadamente.

--- Sobrecalentamiento: La unidad se calienta excesivamente durante el funcionamiento.

--- Ruidos inusuales: zumbidos o zumbidos provienen de la fuente de alimentación.

2. Precauciones de seguridad

Antes de solucionar problemas, asegúrese de lo siguiente:

--- Desconecte la energía para evitar descargas eléctricas.

--- Utilice herramientas aisladas cuando trabaje con circuitos activos.

--- Familiarícese con las especificaciones y el manual de la fuente de alimentación.

3. Pasos para la solución de problemas

Paso 1: inspeccionar la potencia de entrada

Verifique el voltaje de entrada:

--- Utilice un multímetro para verificar si la fuente de alimentación recibe el voltaje de entrada correcto según lo especificado (por ejemplo, 85–264 VCA para muchos modelos).

--- Asegúrese de que la fuente de entrada (por ejemplo, la red eléctrica) sea estable y esté dentro del alcance.

Inspeccionar las conexiones de entrada:

--- Verifique si hay cables sueltos, corroídos o dañados.

--- Confirme la polaridad para los sistemas de entrada de CC.

Paso 2: medir el voltaje de salida

Desconecte la carga:

--- Retire todos los dispositivos conectados para aislar la fuente de alimentación.

Salida de medida:

--- Utilice un multímetro para probar el voltaje de salida en los terminales.

--- Compare el valor medido con el voltaje de salida nominal (por ejemplo, 12 V, 24 V CC).

Paso 3: examinar la carga

Verifique si hay sobrecarga:

--- Asegúrese de que la carga conectada no exceda la capacidad de la fuente de alimentación.

Inspeccionar dispositivos:

--- Verifique que los dispositivos conectados funcionen correctamente y no estén en cortocircuito.

Vuelva a conectar dispositivos individualmente:

--- Agregue gradualmente dispositivos nuevamente al sistema para identificar los problemáticos.

Paso 4: inspeccionar el cableado y las conexiones

Examinar cables:

--- Busque cables deshilachados, dañados o de tamaño insuficiente que puedan provocar caídas de voltaje o cortocircuitos.

Apretar terminales:

--- Asegúrese de que todos los terminales de entrada y salida estén conectados de forma segura.

Paso 5: prueba de cortocircuitos

Terminales de salida:

--- Use un multímetro para verificar la continuidad entre los terminales de salida positivo y negativo. Una lectura que indica un cortocircuito sugiere un problema.

Dispositivos conectados:

--- Inspeccione si hay cortocircuitos internos en los dispositivos de carga o el cableado.

Paso 6: Verifique los factores ambientales

Temperatura:

--- Confirme que la fuente de alimentación esté funcionando dentro de su rango de temperatura.

--- Asegúrese de que haya una ventilación adecuada para evitar el sobrecalentamiento.

Ruido eléctrico:

--- Busque dispositivos cercanos que generen interferencias electromagnéticas (por ejemplo, motores, inversores) y reubique la fuente de alimentación si es necesario.

Paso 7: inspeccionar la unidad de fuente de alimentación

Inspección visual:

--- Busque signos de daño, como marcas de quemaduras, condensadores hinchados o componentes rotos.

Ajustar la configuración de salida:

--- Para modelos ajustables, verifique la configuración del voltaje de salida usando el potenciómetro incorporado.

Paso 8: restablecer la fuente de alimentación

Ciclo de energía:

--- Apague la alimentación de entrada, espere unos segundos y vuelva a encenderla.

Reinicio manual:

--- Si la fuente de alimentación tiene un interruptor o botón de reinicio, actívelo para borrar los modos de apagado de protección.

Paso 9: Probar las protecciones

Protección contra sobrecarga:

--- Reduzca temporalmente la carga y verifique si la fuente de alimentación reanuda su funcionamiento normal.

Protección térmica:

--- Deje que la fuente de alimentación se enfríe si se observa sobrecalentamiento y luego reiníciela.

Paso 10: utilice herramientas de diagnóstico

Multímetro:

--- Mide voltaje, corriente y resistencia para detectar anomalías.

Osciloscopio:

--- Analice la forma de onda de salida en busca de irregularidades, como ondulaciones o ruido.

Pinza amperimétrica:

--- Mida el consumo de corriente de los dispositivos conectados para identificar sobrecargas o cortocircuitos.

4. Soluciones basadas en observaciones

| Observación | Posible causa | Solución |

| Sin voltaje de salida | Entrada defectuosa, fallo interno | Verifique la entrada, revise los fusibles internos, reemplace la unidad. |

| Voltaje bajo o inestable | Sobrecarga, componentes defectuosos | Reduzca la carga, inspeccione y reemplace las piezas dañadas. |

| Calentamiento excesivo | Sobrecarga, mala ventilación. | Reduzca la carga, mejore el flujo de aire, reubique la unidad. |

| Operación intermitente | Conexiones sueltas, problemas medioambientales. | Conexiones seguras, abordar interferencias externas. |

| Protección contra cortocircuito activa | Cableado o carga defectuosos | Identifique y repare componentes o cables en cortocircuito. |

5. Cuándo reemplazar la fuente de alimentación

Si los pasos de solución de problemas no resuelven el problema y la fuente de alimentación:

--- Tiene daños internos visibles.

--- No logra entregar el voltaje correcto constantemente.

--- No puede manejar su carga nominal a pesar de que no hay problemas externos.

--- Es mejor reemplazar la unidad con un modelo compatible de alta calidad.

6. Mantenimiento preventivo

--- Inspeccione periódicamente el cableado y las conexiones en busca de desgaste o daños.

--- Mantenga la fuente de alimentación limpia y libre de polvo o residuos.

--- Opere la fuente de alimentación dentro de sus límites especificados.

--- Pruebe periódicamente los voltajes de entrada y salida para garantizar la estabilidad.

Conclusión

un mal funcionamiento Fuente de alimentación en carril DIN A menudo se puede diagnosticar y reparar verificando sistemáticamente el voltaje de entrada, la carga, el cableado, las condiciones ambientales y la propia unidad. Si sigue estos pasos de solución de problemas, podrá identificar la causa raíz y aplicar la solución adecuada. Si el problema persiste o la fuente de alimentación muestra signos de daños graves, considere reemplazarla para garantizar un funcionamiento confiable.